Fiber optic networks have revolutionized modern communication by offering high-speed, high-bandwidth, and long-distance data transmission with minimal signal loss. These networks form the backbone of the telecommunication, internet, and data center industries, ensuring seamless connectivity for millions of users worldwide. However, to maintain their efficiency and reliability, regular maintenance and proper tools are essential.

Why Fiber Optic Network Maintenance is Important

Maintaining a fiber optic network is not just about preventing failures—it’s about ensuring optimal performance, longevity, and cost efficiency.

✔ Minimizing Downtime: Unexpected fiber breaks, signal loss, or weak connections can lead to network failures. Routine maintenance ensures that issues are detected early, preventing costly disruptions.

✔ Maximizing Performance: Dirt, dust, and minor defects in fiber connections can degrade network performance over time. Proper maintenance ensures clean, efficient, and high-speed data transmission.

✔ Preventing Costly Repairs: Ignoring fiber network issues can lead to major breakdowns, requiring expensive repairs or replacements. Investing in maintenance tools helps avoid such expenses.

✔ Ensuring Network Longevity: A well-maintained fiber optic network can last for decades. Proper splicing, testing, and inspection ensure that the infrastructure remains reliable for years.

To effectively maintain a fiber optic network, technicians, engineers, and businesses need the right set of tools. Let’s explore the essential tools required for proper fiber optic maintenance.

1. Fusion Splicing Machine – For Permanent Fiber Connections

A fusion splicing machine is an essential device for joining optical fibers, using an electric arc to melt and fuse them. This process creates a strong, seamless connection with minimal signal loss, making it the most reliable method for fiber optic cable repair and extension.

Why Fiber Splicing Is Essential

🔹 Ensures Low-Loss & High-Strength Connections

Fusion splicing aligns and fuses fiber cores precisely, minimizing optical loss and maintaining signal integrity. This results in efficient data transmission with minimal disruptions.

🔹 Creates Durable, Permanent Connections

Unlike mechanical splicing, fusion splicing provides a long-lasting, stable bond that withstands environmental factors, ensuring reliable performance over time.

🔹 Reduces Signal Attenuation & Network Downtime

By maintaining optimal optical continuity, splicing minimizes signal degradation, enhances network efficiency, and reduces maintenance requirements, leading to lower operational costs and improved uptime.

Recommended Model: Star FFS 9000 Fusion Splicing Machine

The Star FFS 9000 Fusion Splicing Machine, India’s first OEM-manufactured fusion splicer, is engineered for professional fiber optic technicians. Equipped with advanced technology, it guarantees low splice loss, high efficiency, and superior fiber connectivity. Designed for FTTH deployments, backbone networks, and enterprise fiber solutions, the FFS 9000 Ultima offers precision, speed, and durability, ensuring consistent and reliable performance even in the most demanding environments.

2. Optical Time Domain Reflectometer (OTDR) – For Fiber Testing & Fault Detection

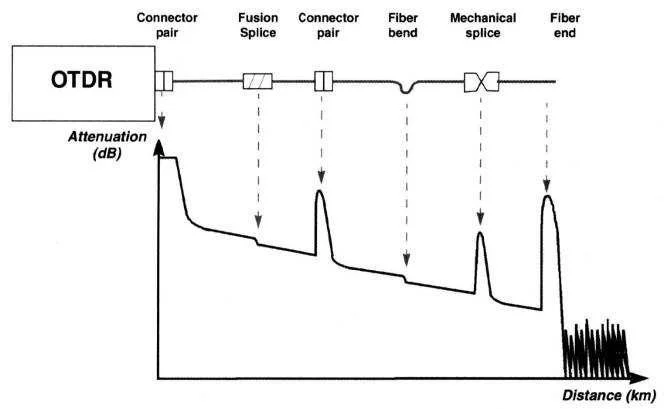

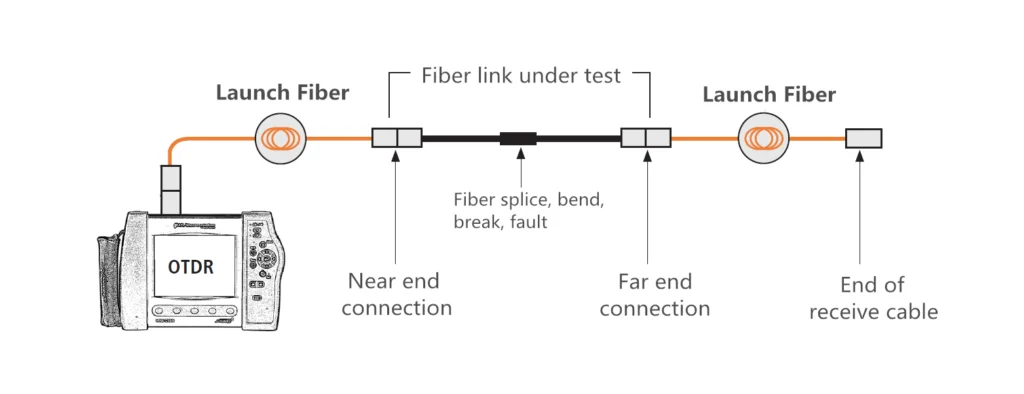

An OTDR is used to analyze the integrity of fiber optic links. It sends light pulses through the fiber and measures reflections to identify fiber length, signal loss, and faults such as breaks, bends, or splices.

Why OTDR Testing Is Essential

🔹 Quick & Accurate Fault Detection

An Optical Time-Domain Reflectometer (OTDR) is a critical tool for fiber optic network maintenance. It quickly pinpoints faults, breaks bends, and other irregularities along the fiber link, reducing troubleshooting time and minimizing network downtime.

🔹 Measures Fiber Attenuation, Splice Loss & Connector Loss

OTDR testing helps analyze signal loss at various points along the fiber. It accurately measures:

- Fiber Attenuation: Identifies signal degradation over distance.

- Splice Loss: Ensures low-loss splicing for high-performance connectivity.

- Connector Loss: Detects issues with terminations that may impact network efficiency.

🔹 Essential for Fiber Link Certification

Network installers and service providers use OTDRs to certify fiber links for compliance with industry standards. This ensures that the network meets quality and performance benchmarks, making it reliable for long-term use.

Recommended Models: Fibershot OTDR – Features & Specifications

The Fibershot OTDR is a high-performance, user-friendly Optical Time-Domain Reflectometer designed for FTTx, PON, metro, access, and long-haul fiber networks. It delivers precise measurements, fast fault detection, and seamless fiber testing, making it an essential tool for network professionals handling installation, maintenance, and troubleshooting.

3. Optical Power Meter & Light Source – For Measuring Signal Strength

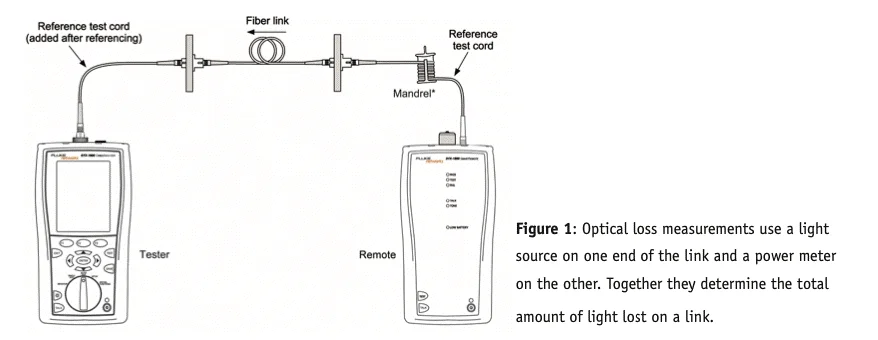

An optical power meter (OPM) is used to measure the power level of fiber optic signals, while a light source is used to send a stable optical signal through the fiber for testing.

🔹 Why It’s Essential

- Measures signal loss and transmission quality.

- Helps verify fiber link performance.

- Ensures compliance with network standards.

Top Fibershot Power Meter Models

The Fibershot Ultima Optical Power Meter ensures high-precision optical power measurement with multi-wavelength support, a bright LCD, long battery life, and USB connectivity for data transfer.

The Fibershot 9090 Handheld Optical Power Meter is a compact and lightweight device designed for portable fiber testing. It features a wide measurement range, auto wavelength recognition, and a rugged design for field use.

The Fibershot MT500 Optical Power Meter offers accurate power detection, quick response time, and multiple wavelength calibration. Its rechargeable battery and user-friendly interface make it ideal for professional fiber testing.

4. Fiber Optic Cleaver – For Precise Fiber Cutting

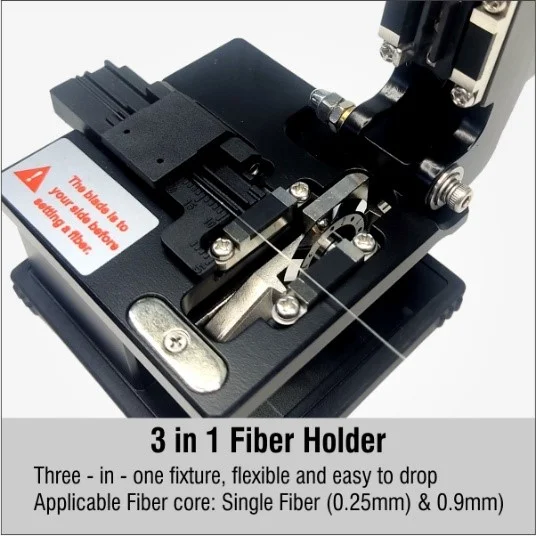

A fiber cleaver is used to cut optical fibers cleanly before splicing. A precise cut is essential for high-quality splices with minimal signal loss.

🔹 Why It’s Essential:

- Ensures precise fiber cutting for fusion splicing.

- Reduces splice loss and improves splicing accuracy.

- Increases the durability of fiber connections.

Star Fiber Cleaver

Fiber Cleaver ensures precise fiber cutting for low splice loss and high-quality fusion splicing. With a durable diamond blade, it delivers over 48,000+ cleaves for long-lasting performance. The auto-cleaving mechanism enhances fiber optic splicing accuracy while reducing manual errors. Its compact and ergonomic design makes it ideal for FTTH, FTTx, and fiber network installations. Built for durability and efficiency, this cleaver ensures seamless fiber optic connectivity with minimal signal loss.

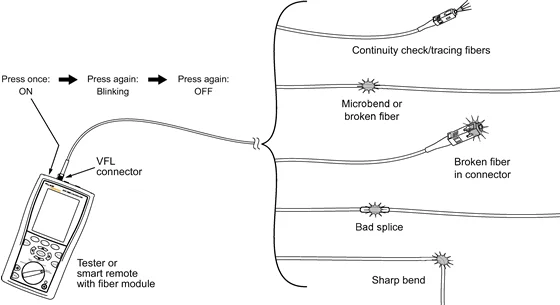

5. Visual Fault Locator (VFL) – For Quick Fault Identification

A Visual Fault Locator (VFL) is a small, handheld tool that emits a bright red laser light into the fiber to locate breaks, bends, and faults.

🔹 Why It’s Essential:

- Quickly identifies fiber breaks and connector faults.

- Helps with fiber routing and continuity testing.

- Easy to use in both indoor and outdoor environments.

The Star Technologies VFL features a 30 km range with a high-power red laser for precise fiber fault detection. Its compact, durable design ensures reliability in FTTH, FTTx, and telecom applications. With a universal connector, it offers seamless compatibility for efficient fiber troubleshooting.

6. Fiber Optic Microscope – For Connector Inspection

A fiber optic inspection microscope is used to check fiber end faces for contaminants, scratches, and defects. Even microscopic dust particles can cause signal loss, making regular inspection crucial.

🔹 Why It’s Essential:

- Ensures fiber connectors are clean and defect-free.

- Prevents performance degradation due to contamination.

🔹 Key Features to Look for:

- 200x-400x magnification for detailed inspection.

- Wi-Fi connectivity for remote monitoring.

- Auto-focus and digital display for ease of use.

The Portable Fiber Optic Inspection Microscope is a high-precision tool designed for fiber professionals, ensuring accurate installation, maintenance, and troubleshooting. It features a 3.5-inch LCD screen for clear defect detection, interchangeable adapters for SC, FC, and LC connectors, and an integrated light source for enhanced visibility. With a rugged yet ergonomic design, it is ideal for both field and lab use, ensuring optimal fiber network performance.

Additional Tools for Fiber Optic Maintenance

- Fiber Optic Cleaning Kit – Includes lint-free wipes, isopropyl alcohol, and swabs for cleaning fiber connectors.

- Fiber Strippers & Kevlar Scissors – Helps safely remove fiber coatings without damaging the core.

- Fiber Optic Tool Kits – A complete set of tools including pliers, strippers, and crimpers for quick fieldwork.

Conclusion

Maintaining a fiber optic network maintenance is essential for ensuring high-speed data transmission, minimal downtime, and long-term reliability. Investing in fiber optic testing tools like fusion splicers, OTDRs, optical power meters, visual fault locators, and fiber optic cleavers helps prevent costly repairs and enhances network performance. Regular maintenance with fiber optic inspection and cleaning kits ensures optimal signal quality and reduces data loss. By equipping professionals with the best fiber optic maintenance tools, businesses can achieve seamless connectivity, improved efficiency, and long-lasting fiber network performance.

Request Call Back

Request Call Back WhatsApp us

WhatsApp us