In the fast-paced world of fiber optics, splicing is critical to ensuring that fiber optic cables maintain their performance and integrity over long distances. Whether you’re working on FTTX networks, long-haul telecommunications, or high-speed internet infrastructure, the method used for splicing depends heavily on the type of fiber Single—Mode (SM) or Multi-Mode (MM). Understanding the differences between these two types of fiber is key to selecting the right fusion splicer and technique.

What are Fiber Optic Cables?

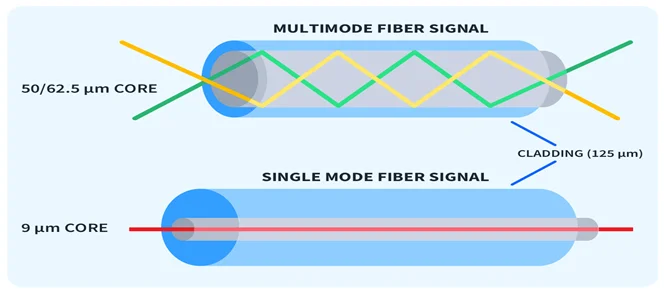

A fiber optic cable or optical fiber cable is a medium used for transmitting optical signals from one place to another. It consists of a strand of glass fibers inside an insulated casing. Fiber optic cable comprises a core, cladding, and a buffer. The core is the central part of the fiber where the light travels. The cladding is a material that surrounds the core and has a lower refractive index. The buffer is a material that surrounds the cladding and protects the fiber from damage.

What is Single-Mode (SM) Fiber?

Single-mode fiber (SM) is designed to carry light signals in a single path, minimizing signal loss and allowing data to travel longer distances with higher bandwidth. With its small core size (typically 8 to 10 microns in diameter), SM fiber is ideal for applications in long-distance networks, such as telecommunications, FTTX deployments, data centers, and high-speed internet. SM fiber is commonly used for applications requiring minimal signal degradation, ensuring high-speed data delivery over large geographical areas.

What is Multi-Mode (MM) Fiber?

Multi-mode fiber (MM) has a larger core (50 to 100 microns), which allows light signals to travel in multiple paths. While this results in more signal loss and potential distortion, MM fiber is well-suited for shorter distances. It is typically used in local area networks (LANs), data centers, and building networks where high-speed data transmission over short ranges is needed. MM fiber’s larger core diameter makes it less expensive than SM fiber, which can be advantageous in cost-sensitive environments.

Key Differences in Splicing SM vs. MM Fibers

- Core Alignment:

- SM Fiber: Requires precise core alignment due to its small core diameter, which is typically achieved with advanced splicing machines that feature core alignment technology. Leading fiber optic splicers like the FFS 5000, FFS 7000, and Fujikura models are designed for SM fiber splicing, offering high accuracy.

- MM Fiber: Easier to align, as the larger core provides more tolerance during the splicing process, making it possible to achieve good results with less sophisticated equipment. However, advanced splicing machines such as Inno and Sumitomo models can still improve the overall efficiency.

- Splicing Loss:

- SM Fiber: Achieving low splicing loss (<0.05 dB) is critical for SM fiber, which requires clean cleaving and meticulous alignment. Specialized fusion splicing machines like the Fujikura 70S and FFS 5000 must meet these stringent standards.

- MM Fiber: MM fiber is more forgiving with splicing loss, typically acceptable at around 0.1 dB due to the larger core size, which offers more tolerance.

- Splicing Equipment:

- SM Fiber: High-precision splicing machines with core alignment features, such as the FFS 5000, FFS 7000, and Fujikura 70S, are recommended for SM fiber splicing.

- MM Fiber: Even splicers with cladding alignment capabilities, like the FFS 9000 and Inno View models, can deliver excellent results for MM fiber.

- Applications:

- SM Splicing: Ideal for scenarios where signal integrity and low attenuation are paramount, such as in long-distance telecom networks, FTTX networks, and telecommunications infrastructure.

- MM Splicing: More suitable for short-distance connections, where ease of installation and cost-efficiency are priorities, including data center networking, LANs, and enterprise networks.

Best Practices for Splicing SM and MM Fibers

- Preparation:

- Clean the fibers thoroughly to eliminate contaminants that could increase splicing loss. Using a high-quality fiber cleaver ensures clean and precise cuts.

- For MM fiber, ensure proper fiber diameter compatibility (e.g., 50μm vs. 62.5μm) to avoid misalignment issues.

- Choosing the Right Splicer:

- For SM fibers, invest in splicing machines with core alignment capabilities, such as the FFS 5000, FFS 7000, and Fujikura 70S models.

- For MM fibers, even simpler splicers with cladding alignment like the FFS 9000, Inno View, or Sumitomo models can achieve excellent results.

- Splicing Settings:

- Use manufacturer-recommended settings for arc power and duration based on the type of fiber being spliced. Test splices are crucial to ensure the optimal settings for minimum loss.

- Post-Splicing:

- Protect the splice joint with heat-shrink sleeves to prevent environmental damage.

- Test the splice using an OTDR (Optical Time Domain Reflectometer) to ensure minimal signal loss and high-quality connections.

Challenges in Splicing SM vs. MM Fibers

- SM Fiber:

- Requires higher precision and expertise due to the small core diameter, making it more sensitive to external factors like dust, misalignment, and poor cleaving.

- Fujikura, Sumitomo, and Inno splicing machines with core alignment features are essential for ensuring precise performance.

- MM Fiber:

- While easier to splice, ensuring consistent quality can be difficult, especially if the fibers have different core sizes (e.g., 50μm vs. 62.5μm).

- MM fiber may suffer from higher modal dispersion if not properly aligned, impacting performance in high-speed networks.

Conclusion

Single-mode (SM) and multi-mode (MM) fiber splicing each come with their own set of challenges and requirements. By understanding these differences and following best practices, technicians can ensure high-quality splices and network reliability. When selecting splicing equipment, whether for FTTX deployment, telecommunications, or data center applications, choosing the right fusion splicer is essential for achieving optimal results.

Looking for the best splicing equipment? Explore our range of fusion splicers, including Fujikura 70S, Inno View, FFS 5000, and FFS 7000, and optical tools to find the perfect solution for your network projects. Whether you need precision splicing for long-distance telecom networks or cost-effective solutions for data center networks, we have the equipment to meet your needs.

Request Call Back

Request Call Back WhatsApp us

WhatsApp us