Introduction

Fiber optic networks are the backbone of modern telecommunications, offering high-speed and reliable connectivity. One crucial component in maintaining network integrity is the fiber optic splice closure. These enclosures play a vital role in protecting spliced fiber optic cables from environmental hazards such as moisture, dust, and extreme temperatures, ensuring long-term durability and optimal performance.

A properly selected and installed splice closure helps prevent signal loss and mechanical damage, contributing to a more resilient and efficient network infrastructure. Whether deployed in underground ducts, aerial installations, or direct burial applications.

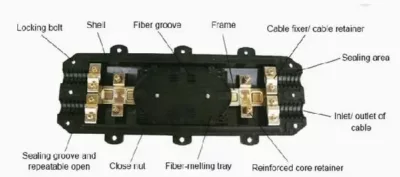

What is a Fiber Optic Splice Closure?

Fiber optic cables are spliced while setting up the network. These sensitive fibers have to be protected from the environment – extreme temperatures, insects, critters, moisture, and pressure. A fiber optic splice closure is a small plastic box that protects the fiber cable inside. These closures are essential in FTTH (Fiber to the Home), FTTX (Fiber to the X), and backbone networks. They ensure fiber integrity by offering robust sealing, efficient cable management, and easy access for future maintenance.

Types of Fiber Optic Splice Closure

1. Dome/Vertical Fiber Optic Closure

The vertical dome fiber optic closure is a widely used solution for underground and direct burial applications. Its dome shape ensures superior sealing and mechanical protection, accommodating 24 to 960 cores. Ideal for network expansion and distribution, it securely houses fiber cables while enabling organized and safe splicing, making it essential for modern telecom infrastructure.

2. In-Line/Horizontal Fiber Splice Closure

Inline (Horizontal) Joint Closures are essential for extending fiber connections seamlessly across network points. With core capacities ranging from 24 to 144, they offer versatility for various network scales. Available in flat or cylindrical designs, these closures can be buried underground or mounted aerially as needed. These closures foster a streamlined pathway for fiber connections, guaranteeing stable and uninterrupted signal transmissions. It’s a choice that brings both versatility and reliability to network setups.

3. Inline (Clamshell) Fiber Splice Closure

The Inline (Clamshell) Joint Closure is noted for its innovative buckle-locking design, a departure from the traditional screw-to-lock mechanisms in other inline closures. It is a favorable option for medium-scale projects and is designed to accommodate a core fiber range of 24 to 48. This modern approach ensures not only a secure closure but also facilitates easier installation and maintenance access, promising efficiency and user-friendliness in network management.

Features of Star Infomatic Fiber Optic Splice Closures

Star Informatic offers high-performance fiber optic splice joint closures designed for both underground and aerial applications. Their products are engineered with the latest technology to provide maximum protection and efficiency.

- IP68-rated waterproof protection for harsh environments

- High-quality ABS and polypropylene materials ensuring durability and resistance to external stress

- Easy installation and re-entry without specialized tools, reducing maintenance costs

- Compatibility with ribbon and loose-tube fiber cables, supporting various network architectures

- Designed for high fiber count capacity, accommodating future network expansions

Installation Guide for Fiber Optic Splice Closures

Step 1: Preparation

- Gather all necessary tools: fiber cleaver, splicing machine, heat shrink sleeves, sealing tape, and cleaning supplies.

- Select the appropriate splice closure type (dome or inline) based on network requirements.

- Ensure all cables are properly labeled for easy identification.

Step 2: Cable Entry & Preparation

- Open the closure and prepare the cable entry ports.

- Strip the outer cable jacket carefully to expose fiber tubes while avoiding fiber damage.

- Secure cables using the provided clamps or gaskets to prevent movement and strain.

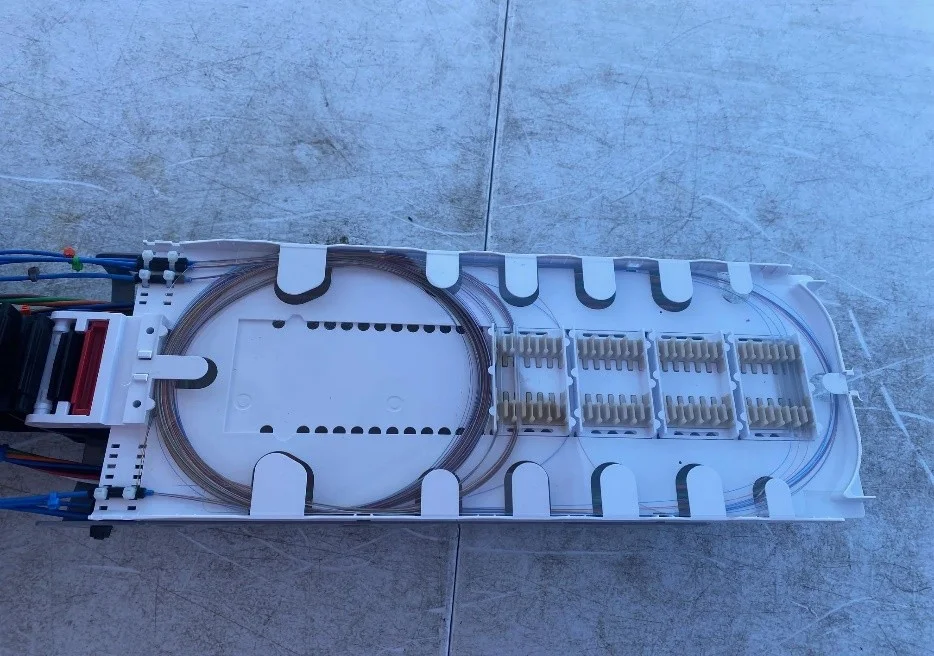

Step 3: Splicing and Fiber Management

- Use a fusion splicer for precise splicing with minimal signal loss.

- Arrange and protect spliced fibers using splice trays for organized cable management.

- Apply heat shrink tubing or mechanical protection to reinforce the spliced areas.

Step 4: Sealing and Closure

- Seal the enclosure using heat-shrink tubing or mechanical gaskets to ensure complete waterproofing.

- Ensure all entry points are properly sealed to prevent dust and moisture ingress.

- Secure the closure in its designated location, whether aerial, underground, or wall-mounted, ensuring it is properly supported.

Maintenance Tips for Long-Term Reliability

Regular maintenance is key to preventing network disruptions and ensuring long-term functionality.

Periodic Fiber Optic Inspections: Regularly check for water ingress, physical damage, or fiber optic cable strain that may impact network performance.

Environmental Protection for Fiber Networks: Ensure fiber optic splice closures are properly sealed and positioned to withstand harsh weather conditions and external elements.

Efficient Fiber Cable Management: Maintain proper fiber optic cable organization within splice trays to prevent excessive bending, stress, or tension.

Re-Sealing After Repairs: Always reapply fiber optic sealing mechanisms after network repairs or upgrades to ensure long-term protection and reliability.

Why Choose Star Infomatic Fiber Optic Splice Closures?

Star Informatic provides high-quality fiber optic solutions designed for superior performance and reliability. Their splice joint closures offer:

- User-friendly design for quick and efficient installation

- Advanced sealing for long-term environmental protection

- High-capacity fiber management for growing networks

- Cost-effective solutions suitable for ISPs, telecom operators, and enterprises

- Robust construction to withstand extreme conditions, ensuring longevity

Conclusion

Proper fiber optic closure maintenance is essential for maximizing the durability and efficiency of fiber optic networks. Regular inspection of fiber closures, thorough cleaning, effective sealing, environmental monitoring, and structured fiber cable management help prevent failures and ensure optimal signal transmission. By following these fiber optic maintenance tips, you can enhance the reliability of fiber optic closures, minimize network downtime, and reduce fiber optic repair costs.

Choosing the right fiber optic splice closure is crucial for ensuring network reliability, durability, and performance. Star Informatics’ fiber optic joint closures offer superior protection, easy installation, and long-lasting performance, making them the preferred choice for network operators looking for high-quality fiber optic solutions worldwide.

Request Call Back

Request Call Back WhatsApp us

WhatsApp us