Introduction

Accurate fiber optic testing is essential for ensuring seamless network performance and minimizing signal loss. An Optical Time-Domain Reflectometer (OTDR) is an indispensable tool used to detect faults, measure fiber length, and ensure a high-performance connection. However, simply owning an OTDR isn’t enough; mastering its use is crucial to obtaining accurate results and optimizing network performance.

Whether you are a seasoned fiber optic technician or just starting, these five must-know OTDR tricks will help you enhance your fiber testing process, reduce troubleshooting time, and improve overall efficiency.

Optimize Your OTDR Settings for Accurate Fiber Testing

To achieve accurate and reliable results, it is essential to configure key OTDR parameters correctly. Adjusting settings such as

- Pulse width

- Event dead zone

- Sampling points

- Laser quality

- Port/connector cleaning

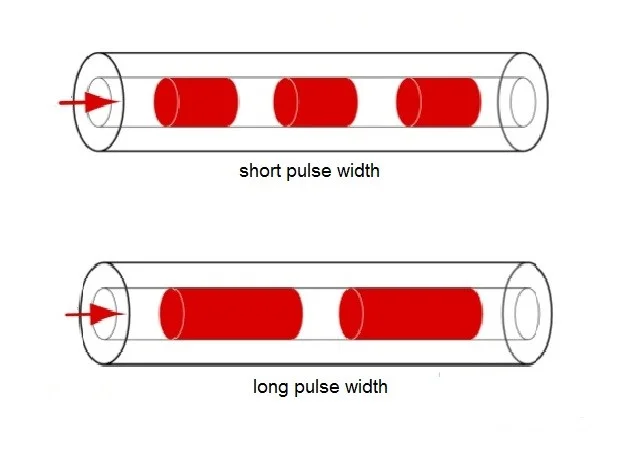

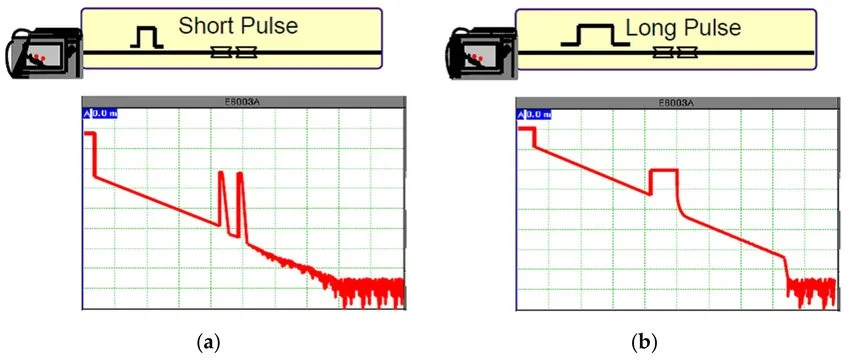

1. What is Pulse Width in OTDR Testing?

Pulse width in an Optical Time-Domain Reflectometer (OTDR) refers to the duration of the laser pulse sent into the optical fiber. It determines the amount of light energy used for testing and significantly affects the range, resolution, and accuracy of the OTDR trace.

Resolution vs. Distance Trade-off

The FFS-9000 features a 4.3-inch high-resolution LCD Screen that simplifies the splicing process. The intuitive graphical interface allows users to navigate settings effortlessly, reducing the learning curve and enhancing operational ease.

Short Pulse Width → Higher Resolution, Shorter Distance

- Ideal for detecting closely spaced events such as splices, connectors, and faults in short fiber runs.

- Provides detailed traces but limits the testing range.

Long Pulse Width → Lower Resolution, Longer Distance

- Suitable for long-haul fiber networks where a longer range is required.

- Can miss small reflective events due to reduced resolution.

| Pulse Width | Resolution | Testing Range | Best Application |

| Short (3-100ns) | High | Short (1-5km) | FTTH, LAN, FTTx |

| Medium (100-500ns) | Balanced | Medium (5-50km) | Metro Networks |

| Long (500ns-10µs) | Low | Long (50-150km) | Long-haul, Backbone |

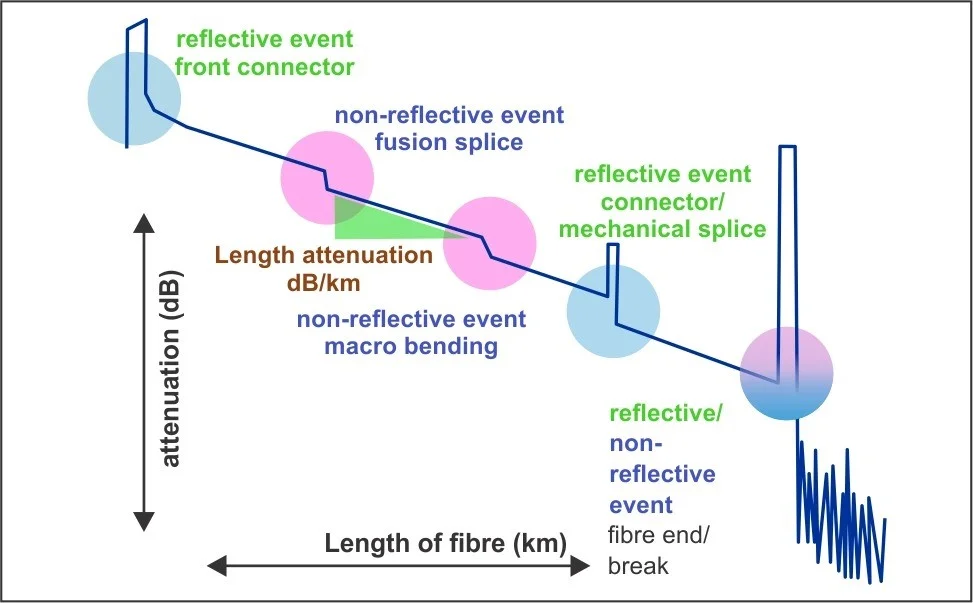

2. Event Dead Zone- improve Fault Detection in Short Fiber Runs

The event dead zone (EDZ) is the minimum distance required between two reflective events for the Optical Time-Domain Reflectometer (OTDR) to distinguish them as separate events. A smaller dead zone is crucial for high-precision fiber testing, especially in FTTH networks, data centers, and dense fiber infrastructures.

Impact on Testing

- Short fiber runs: A large dead zone can cause missed faults in dense fiber networks like data centers where connections are close together.

- FTTH (Fiber to the Home): Due to the short fiber lengths involved, accurate fault detection requires an OTDR with a small dead zone.

Factors affecting dead zone size

- OTDR pulse width: Narrower pulses generally result in smaller dead zones.

- Reflection strength: Higher reflection levels can lead to a longer dead zone.

Choose an OTDR with a short event dead zone (<1m) for better accuracy in short-distance fiber testing.

3. Sampling Points in OTDR Testing

In OTDR (Optical Time-Domain Reflectometer) testing, Sampling points refer to the individual data points collected along the fiber optic link to create a detailed trace or measurement profile. These points represent reflected signals at different locations along the fiber, allowing the OTDR to detect events such as splices, bends, connectors, and faults.

Why Are Sampling Points Important?

✔ Higher Sampling Points = Greater Detail & Accuracy

- More sampling points allow for better event detection, particularly in short fiber links with multiple splices and connectors.

- High sampling density provides clearer visualization of fiber faults and more precise loss measurements.

✔ Lower Sampling Points = Faster Testing

- Reducing sampling points speeds up the OTDR test but may lead to missing small details, such as micro bends or minor connection losses.

- Ideal for quick testing when a detailed trace is not required.

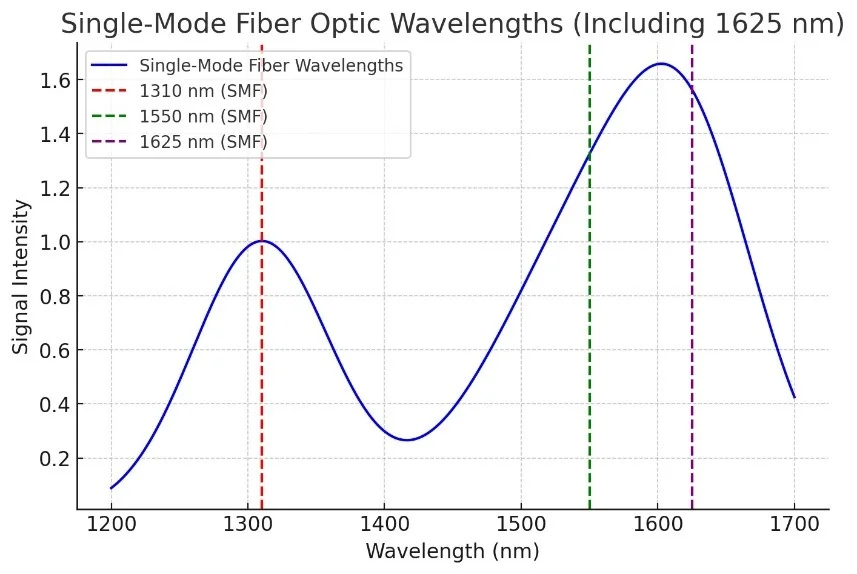

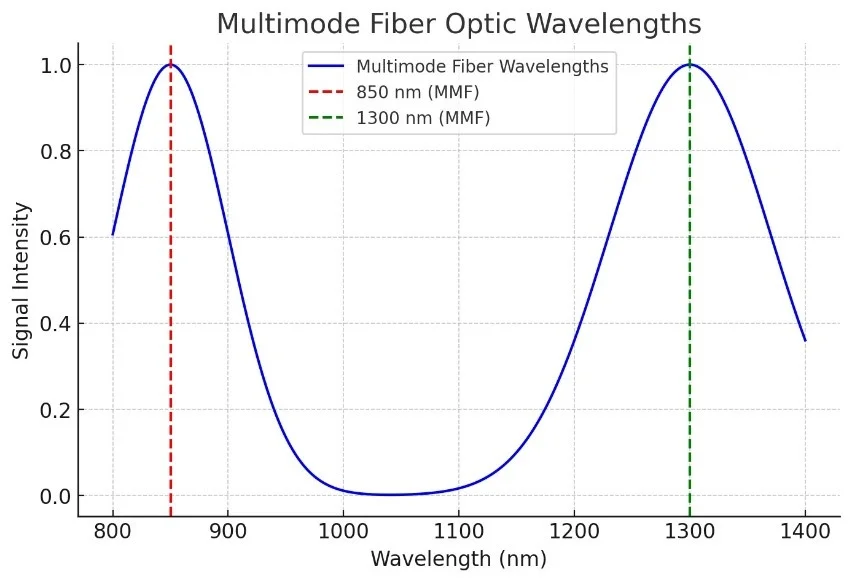

4. Understanding OTDR Wavelengths

OTDRs operate at different wavelengths depending on the type of fiber being tested—single-mode or multimode. Each wavelength has unique characteristics that influence attenuation, bend sensitivity, and suitability for various applications. Choosing the correct wavelength is essential for obtaining accurate fiber loss measurements, detecting faults, and ensuring reliable fiber optic network performance.

Wavelengths Used in OTDR Testing

The 1310 nm wavelength is commonly used for short to medium-distance fiber testing because of its lower fiber attenuation (~0.33 dB/km). It is ideal for troubleshooting fiber splices, connectors, and short-haul communication networks such as FTTx (Fiber to the Home/Building), metro networks, and enterprise fiber links.

1550 nm is the preferred wavelength for long-haul fiber optic networks because it experiences less attenuation than 1310 nm. However, bending loss is significantly higher at 1550 nm, making it useful for identifying fiber bends, macro bends, and other structural weaknesses.

1625 nm is typically used for in-service OTDR testing, allowing fiber network operators to monitor fiber health without disrupting active traffic. This wavelength is commonly used in maintenance and monitoring applications to detect fiber degradation, bends, and aging effects over time.

Multimode fiber is widely used in data centers, enterprise LANs, and short-distance communication networks. The two standard wavelengths for multimode OTDR testing are:

- 850 nm: Used for short-range fiber testing. It has a higher attenuation (~2.5 dB/km) but allows for higher data transmission rates in multimode fibers.

- 1300 nm: Used for longer multimode fiber links because it has lower attenuation (~0.6 dB/km) than 850 nm.

Choosing the Right OTDR Wavelength

| Wavelength | Fiber Type | Best Use Case | Attenuation | Sensitivity to Bends |

| 1310 nm | Single-mode | Short to Medium-range networks (Metro, FTTx, Enterprise) | ~0.35 dB/km | High |

| 1550 nm | Single-mode | Long-haul networks, DWDM, Submarine cables | ~0.20 dB/km | Moderate |

| 1625 nm | Single-mode | Live fiber monitoring and maintenance | ~0.25 dB/km | High |

| 850 nm/1300nm | Multimode | Short-distance, LAN, Data Centers | ~2.5 dB/km | Low |

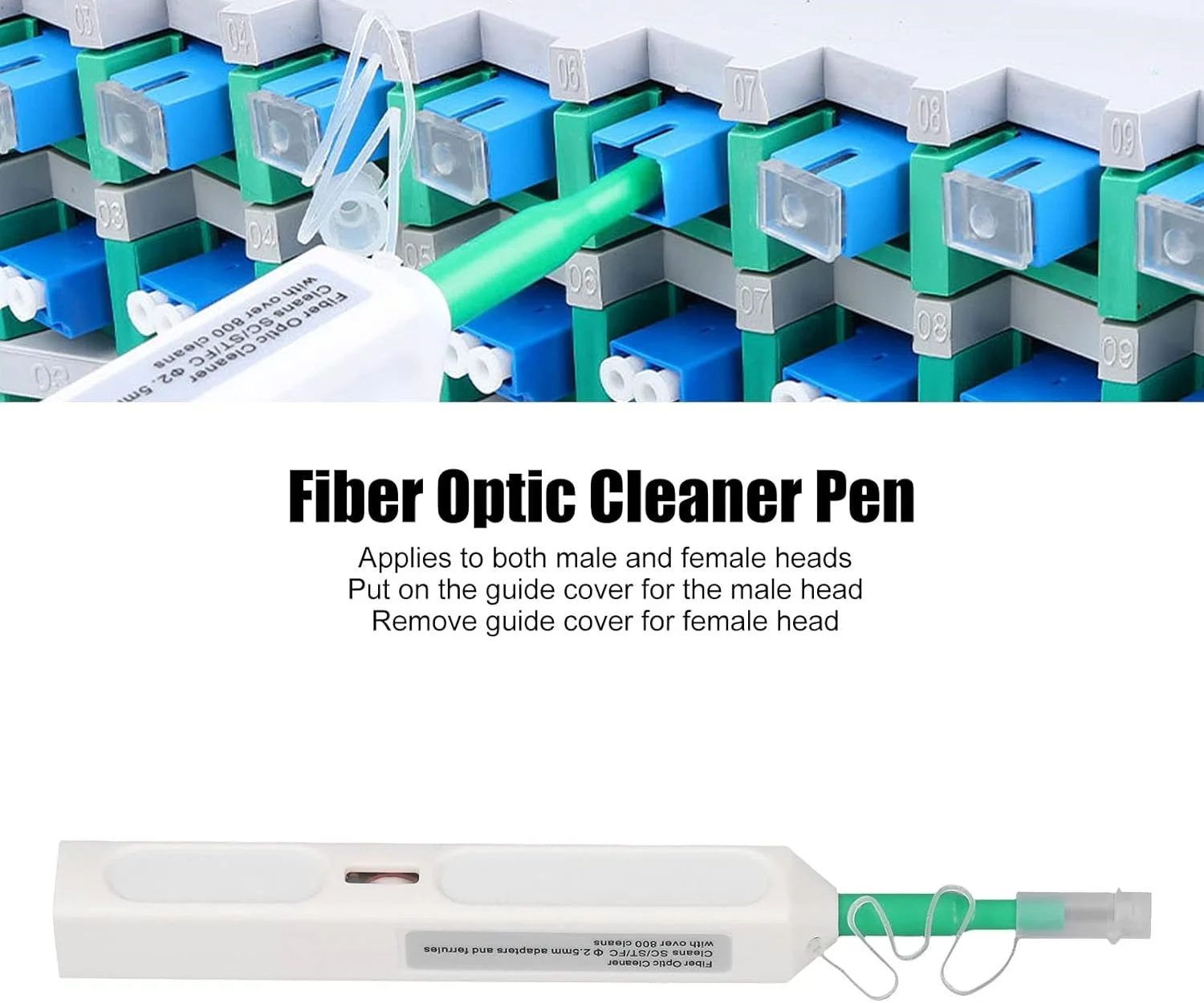

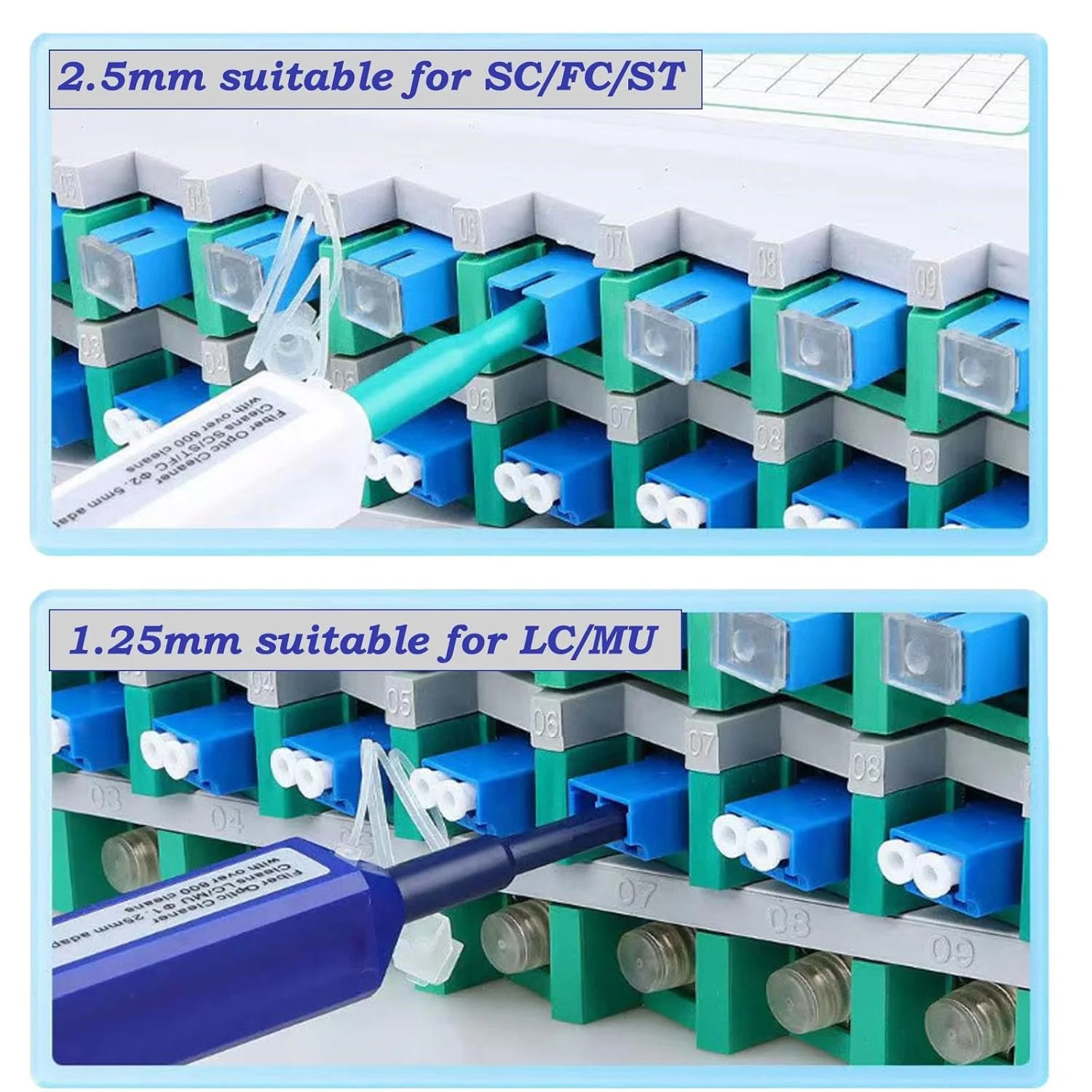

5. OTDR Port Connector Cleaner

A clean OTDR port connector is crucial for accurate fiber-optic testing. Contamination can cause inaccurate readings, signal loss, and equipment damage. Regular cleaning ensures optimal performance and longevity.

Why Cleaning the OTDR Port Connector is Important?

- Ensures Accurate Measurements – Contaminants like dust, dirt, and oil can interfere with signal transmission, leading to incorrect test results.

- Prevents Signal Loss and Reflection – A clean port reduces attenuation and reflections, providing precise readings.

- Extends Equipment Lifespan – Regular cleaning prevents damage to the OTDR’s internal components, reducing repair costs.

- Improves Fiber Connector Durability – A dirty OTDR port can contaminate fiber connectors, affecting overall network performance.

Request Call Back

Request Call Back WhatsApp us

WhatsApp us