Fiber optic connectors are crucial for creating reliable, low-loss links between fiber optic cables. As global networks continue to grow at an unprecedented pace, selecting the right connector is vital to maintaining stable data transmission, supporting scalability, and future-proofing telecom infrastructure.

At Star Infomatic Pvt. Ltd., we provide a comprehensive range of passive fiber connectivity solutions designed to meet the dynamic requirements of ISPs, telecom operators, government agencies, and enterprise customers.

Optical Fiber Connector

An Optical Fiber Connector is a device used to join optical fibers end-to-end, enabling efficient light signal transmission with minimal loss. It provides a secure, precise, and removable connection between fibers, essential for flexible network setups and easy maintenance in fiber optic communication systems

Types of Fiber Optic Connectors and Their Applications

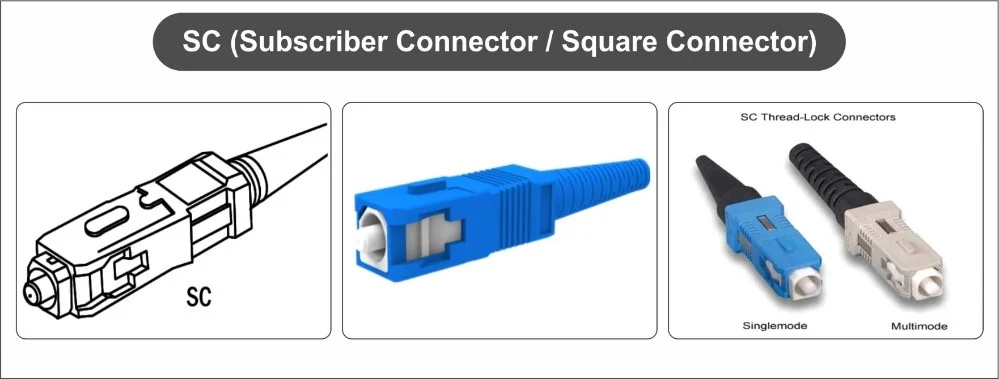

1. SC (Subscriber Connector / Square Connector)

The SC connector is one of the most commonly used fiber optic connectors. It features a push-pull mechanism, making it easy to insert and remove while ensuring a stable connection.

- Used in telecom, GPON, EPON, PON, and FTTH applications for long-distance transmission at wavelengths of 1310 nm or 1550 nm.

- Connector Type: Available in SC/APC (Angled Physical Contact) for reduced reflection and SC/UPC (Ultra Physical Contact) for lower insertion loss.

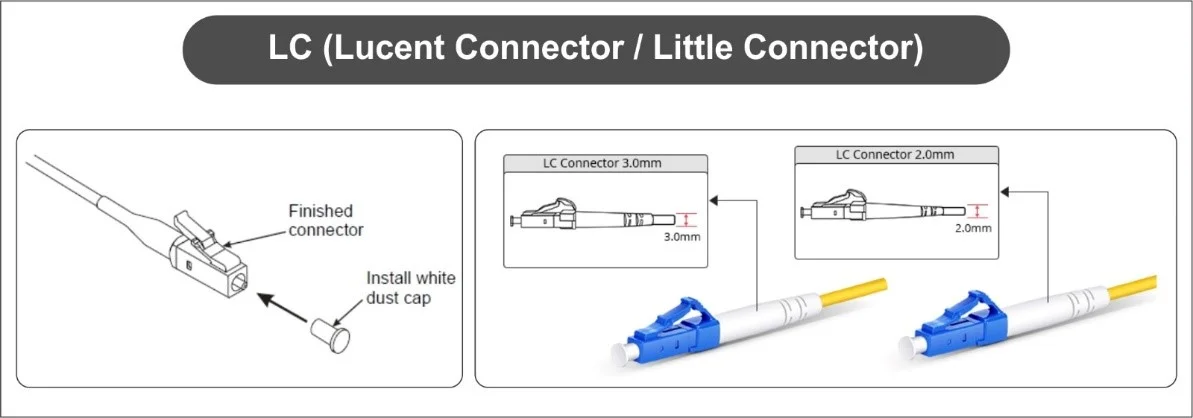

2. LC (Lucent Connector / Little Connector)

The LC connector is a compact, small form factor (SFF) fiber optic connector with a 1.25 mm ferrule and a push-latch mechanism, ideal for high-density applications.

It supports both single-mode (core: 8–10 µm) and multimode (core: 50/125 µm or 62.5/125 µm) fibers.

USE Case: ONTs, SFP ports in dense networks, FTTH accessories, and high-density data centers.

View: LC Pigtails & Adapters

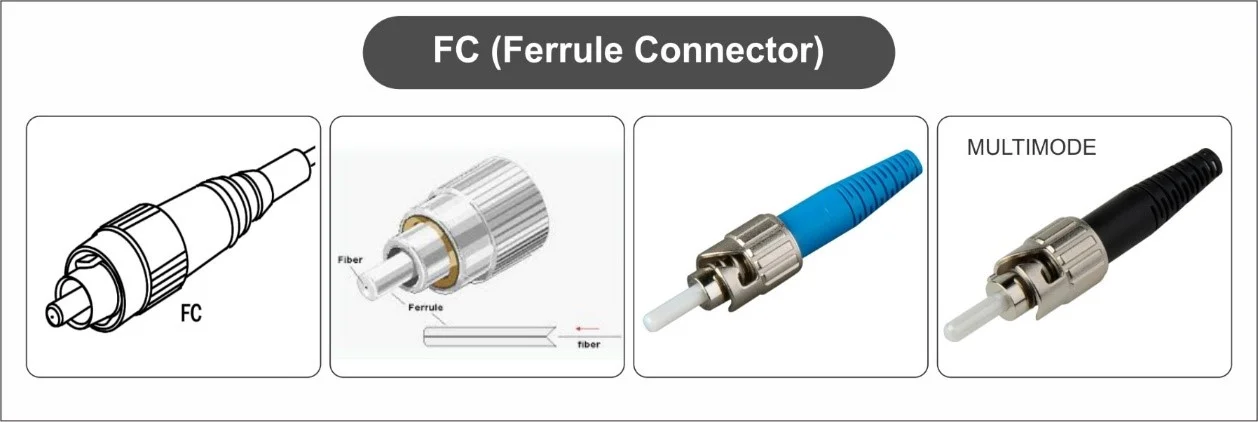

3. FC (Ferrule Connector)

FC connectors feature a screw-on design for secure connections. Ideal for telecom, datacom, and test equipment, especially in high-vibration environments.

Explore: FC Tools & Accessories

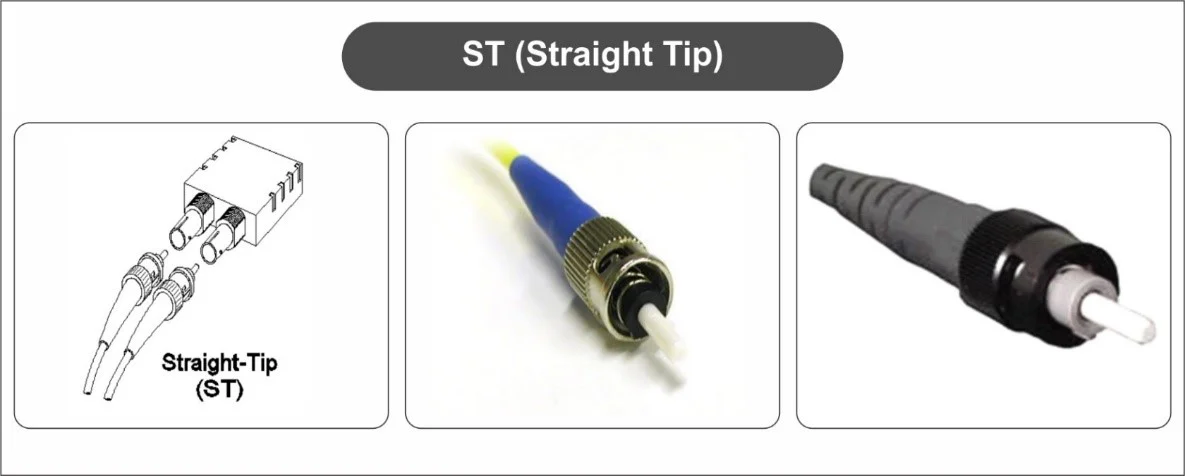

4. ST (Straight Tip)

ST (Straight Tip) connectors feature a bayonet-style twist-lock design and a 2.5mm ferrule. Also available for single-mode fiber with color-coded boots.

Application: Common in FDDI networks and multimode fiber, mainly used in LANs and campuses, and short-distance fiber links.

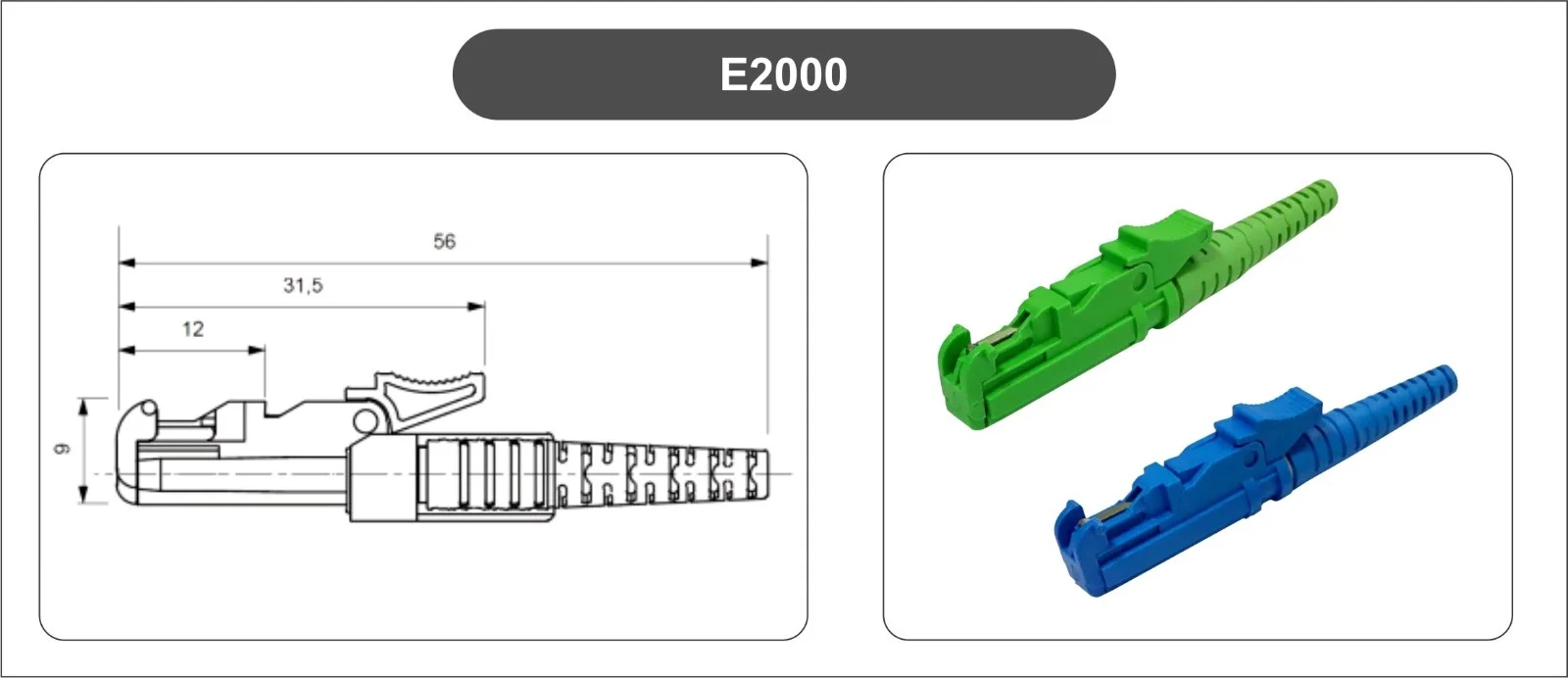

5. E2000

It features a built-in automatic shutter that protects against dust and accidental laser exposure, ensuring safety and reliability.

- High-speed data transmission E2000 connector delivers excellent performance and durability in demanding environments.

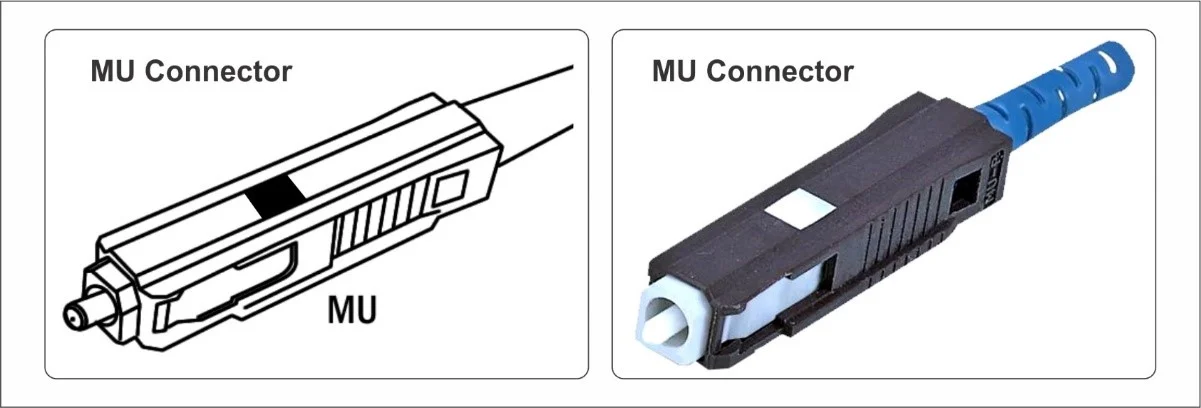

6. MU Connector (Miniature Unit or Mini-SC)

A compact, high-density fiber optic connector with a 1.25mm ferrule and push-pull mechanism, developed by NTT, it offers a space-saving design and precise alignment for efficient optical performance.

- Form Factor: ideal for data centers, DWDM, telecom, and test instruments.

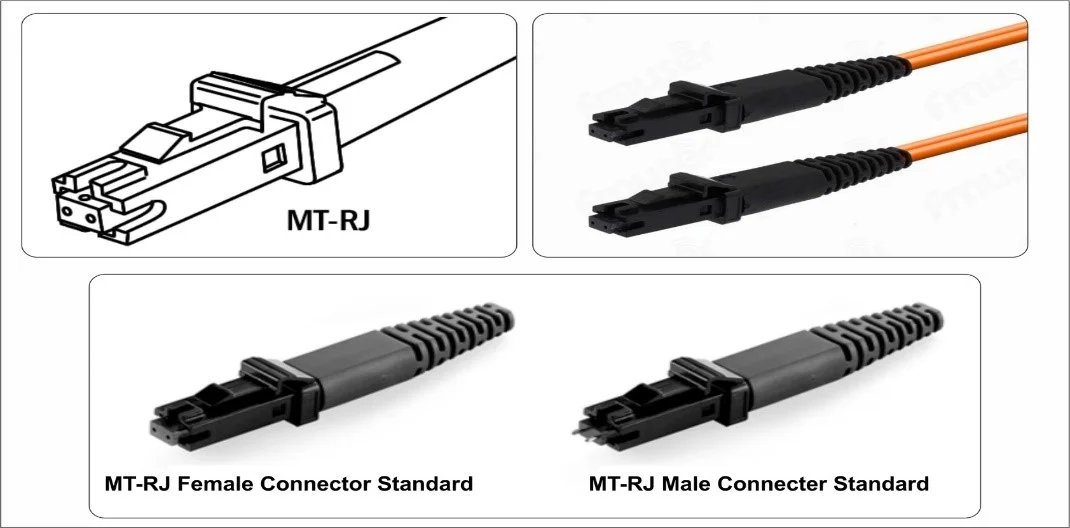

7. MTRJ Connector (Mechanical Transfer Registered Jack)

A compact duplex fiber optic connector with an RJ45-like design, supporting two fibers in one housing.

- Ideal for high-density telecom and data network It’s cost-effective, easy to use, and commonly used in fiber-to-the-desktop and indoor networking.

- Features include push-pull latching, pin alignment, and easy connection.

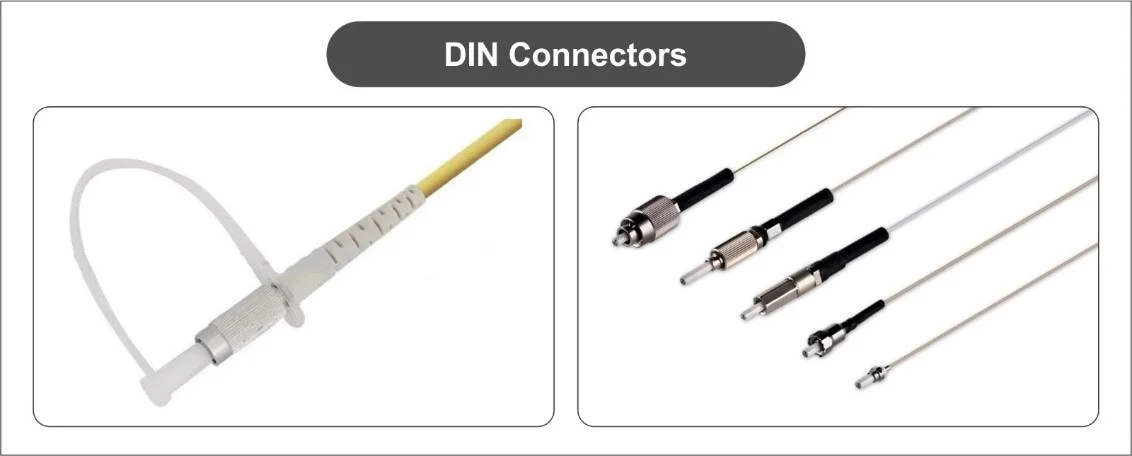

8. DIN Connectors

- DIN connectors are circular or cylindrical multi-pin electrical connectors

- Commonly used for audio/video, data communication (e.g., MIDI), and power supply

Also used for connecting PC peripherals (pre-USB era)

- Standard DIN: Pins arranged in a circular pattern

- Mini-DIN: Smaller, with pins in horizontal rows

9. MPO/MTP (Multi-Fiber Push-On / Multi-fiber Termination Push-on)

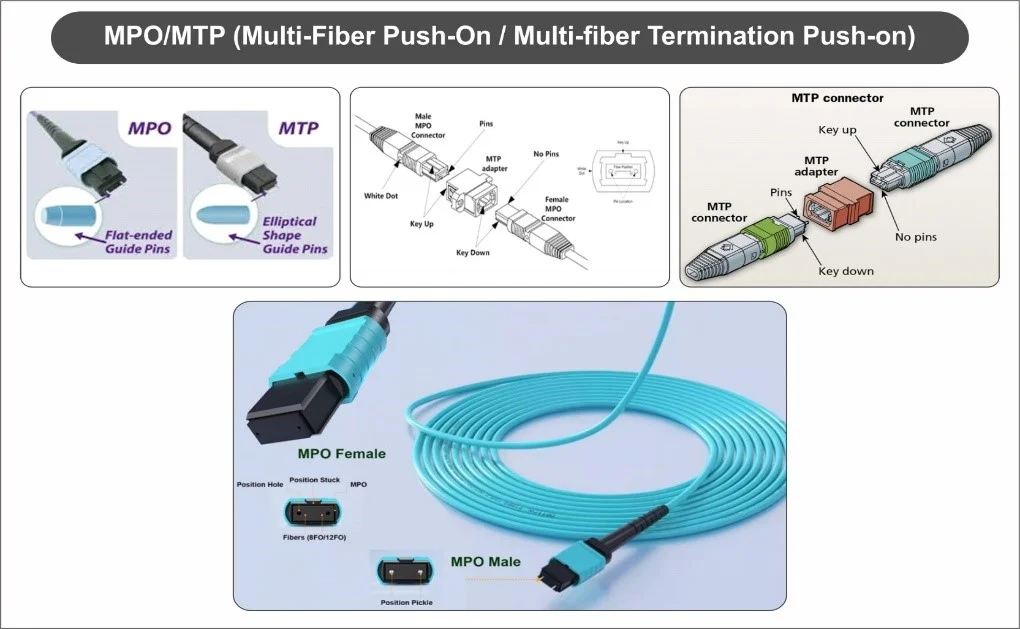

- MPO (Multi-Fiber Push-On) and MTP (Multi-Fiber Termination Push-On) are high-density fiber optic connectors designed for fast and efficient data transmission.

- Feature: Supports ribbon fiber, typically with 12, 24, or 48 fibers per connector.

- Common Applications: Data centers, 40G/100G/400G networks, and backbone cabling.

- Advantage: MTP is an enhanced version of MPO, offering better performance and precision alignment.

- Used: data centers, telecommunications, and enterprise networks.

SOC (Splice on Connector)

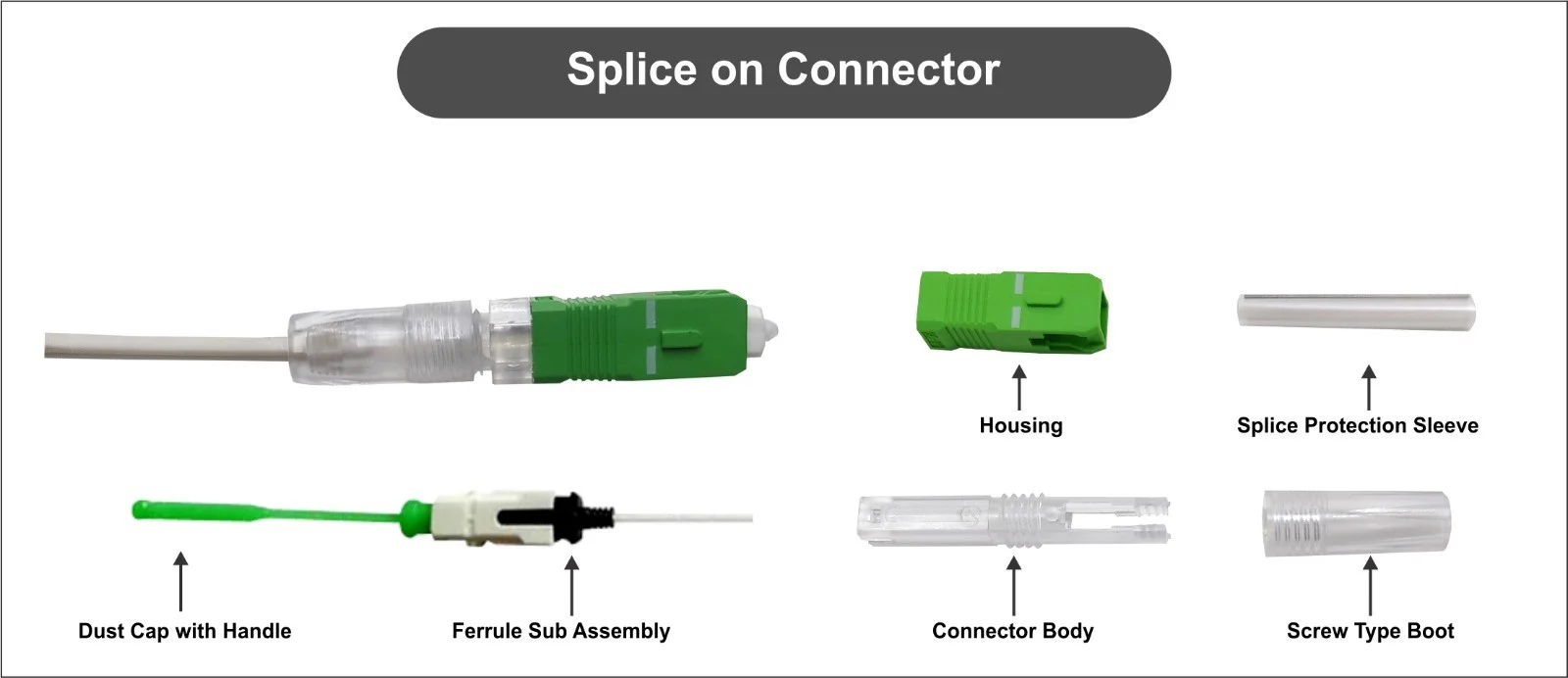

Splice-On Connectors (SOC) are a modern alternative to factory-terminated fiber optic connectors. Instead of relying on pre-assembled patch cords or connectors, SOCs allow technicians to terminate fiber optic cables directly in the field using a fusion splicer. This method merges a standard fiber optic connector with a short pigtail fiber that is fused to the main cable using heat.

- Factory-like performance with field flexibility

- Low insertion loss and high return loss

Custom cable lengths with quick deployment

1. High-Precision Core Alignment for Low-Loss Splicing

- Both FFS 5000 and FFS 7000 use advanced core alignment for ultra-low splice loss (<0.1 dB) and high return loss (>60 dB)

- Accurate alignment between the fiber in the field and the pigtail fiber inside the SOC connector

- Minimal signal loss and strong mechanical connection

- Reliable long-term performance equivalent to factory-terminated cables

2. Easy Field Termination Process

- Field technicians can use Star splicers to complete SOC installations on-site without needing factory-prepared connectors or long lead times.Strip → Clean → Cleave → Splice → Heat Shrink → Done!Typical termination time: less than 2 minutes per connector

3. Built-In SOC Termination Modes & Software Integration

- Both FFS 5000 and FFS 7000 models include dedicated SOC termination modes (SC, LC, FC, etc.).

- Automatically adjust splice/heat settings for each connector.

- Touchscreen guides help all technicians achieve consistent results.

- Ideal for both experienced and less-experienced technicians, these modes help speed up deployment and ensure uniform, high-quality splices every time.

4. Built-in Testing, Reporting & Quality Assurance

Both splicers feature integrated tools to maintain high quality and accountability:

- Automatic splice evaluation verifies the integrity of each SOC splice

- Data logging and reporting capabilities track splice results for documentation and quality control

- Enables technicians to confidently verify and certify every field-terminated splice before completing the job

5. Full Compatibility & Rugged Portability for Field SOC Termination

- Compatible with SC/APC, LC/UPC, FC/UPC, and custom connectors.

- Universal SOC holders are included in both models.

- Rugged, weather-resistant, and portable design.

- Long battery life: over 100 splices per charge with both splicers—ideal for field use.

Best Use Cases for Fusion Splice-On Connectors

FTTH (Fiber to the Home) Installations for homes and businesses

Last-Mile Connectivity projects

Data Centers and Enterprise Networks setups

Backbone Fiber infrastructure

Telecom and CATV Networks deployments

Design Considerations for Fiber Optic Connectors

Fiber optic connectors are designed for optimal performance and durability, focusing on ferrule material, polishing type, form factor, and boot design to suit various network needs.

1. Ferrule Material

- Ceramic (Zirconia): High precision and stability, ideal for single-mode and multimode fibers.

- Stainless Steel: Durable and impact-resistant, used in industrial/military settings, but less precise.

- Plastic: Cost-effective for temporary or indoor use, not suited for high-performance needs.

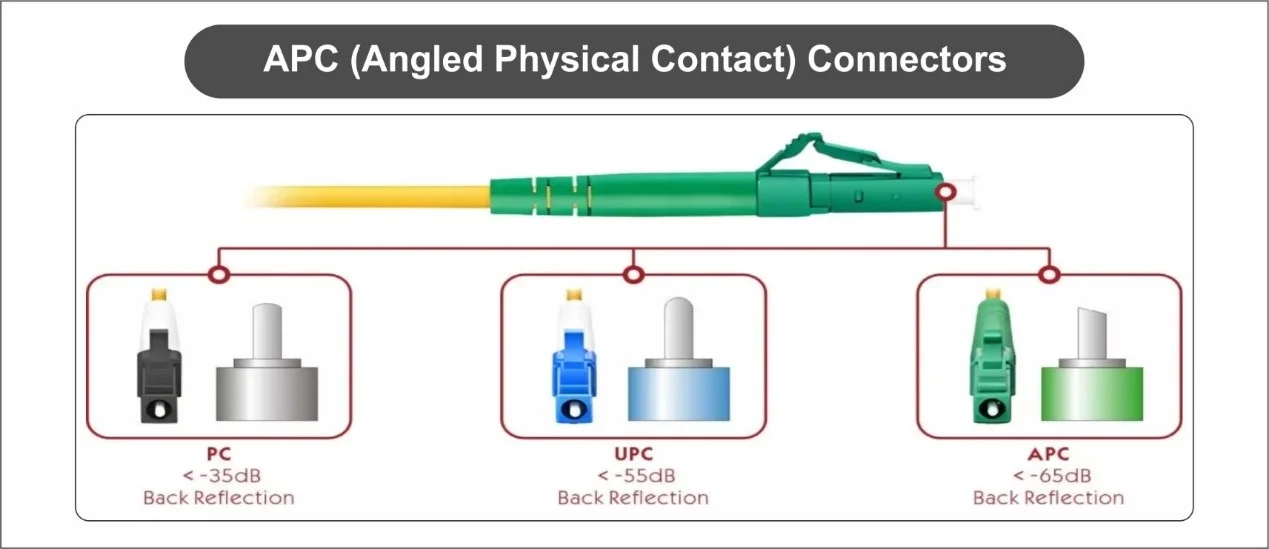

2. APC vs. UPC – Which Connector to Choose?

-

- UPC (Ultra Physical Contact): Flat polish, low return loss (~ -50 dB), suitable for data centers, LANs, and short to medium distances.

- APC (Angled Physical Contact): 8° angled polish, very low return loss (≥ -60 dB), ideal for FTTH, long-haul, and RF applications requiring minimal signal reflection.

Differences Between PC, UPC, and APC Connectors Type Polish Angle Color Code Return Loss Insertion Loss Application PC 0° (slight curve) Black ~ -40 dB ≤ 0.3 dB General-purpose, legacy systems UPC 0° (more refined) Blue ~ -50 dB ≤ 0.25 dB LANs, test ports, FTTH OLT APC 8° angled Green ≥ -60 dB ≤ 0.3 dB FTTH, CATV, RF-over-fiber, long-haul GPON, CATV

✅ Choose the Right Connector with Star’s APC/UPC Kits

Star Technologies offers a full range of APC and UPC Connector Kits, compatible with all major fusion splicers, including our FFS 5000 and 7000 series. These kits are designed for:

- Field-ready performance

- Consistent polish and low-loss termination

- Support for SC, LC, and FC connector types

Whether you’re building a GPON network, deploying FTTH, or maintaining a data center, Star’s connector kits ensure you get the best performance with the right polish type for your application.

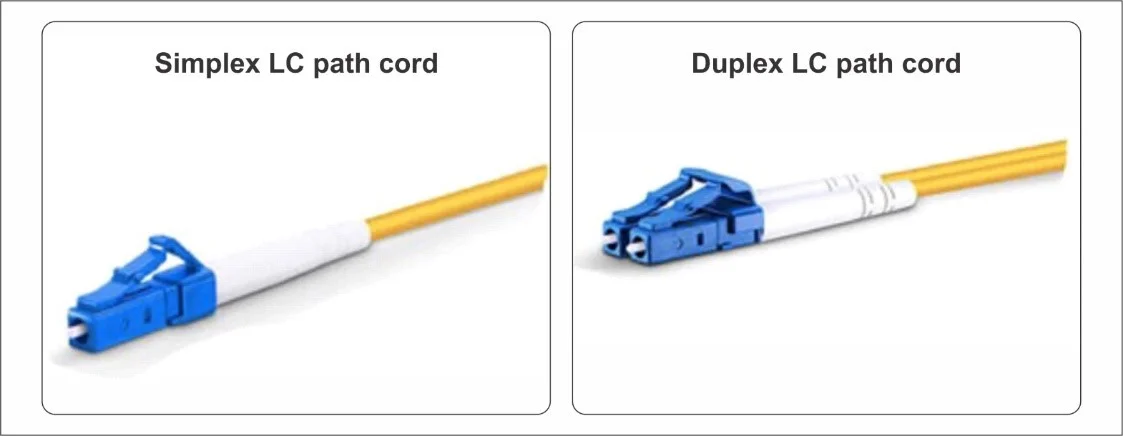

3. Simplex vs. Duplex Fiber

- Simplex: One-way signal transmission; ideal for sensors and single-direction data flow.

- Duplex: Two-way signal transmission; commonly used in FTTH, enterprise networks, and telecom.

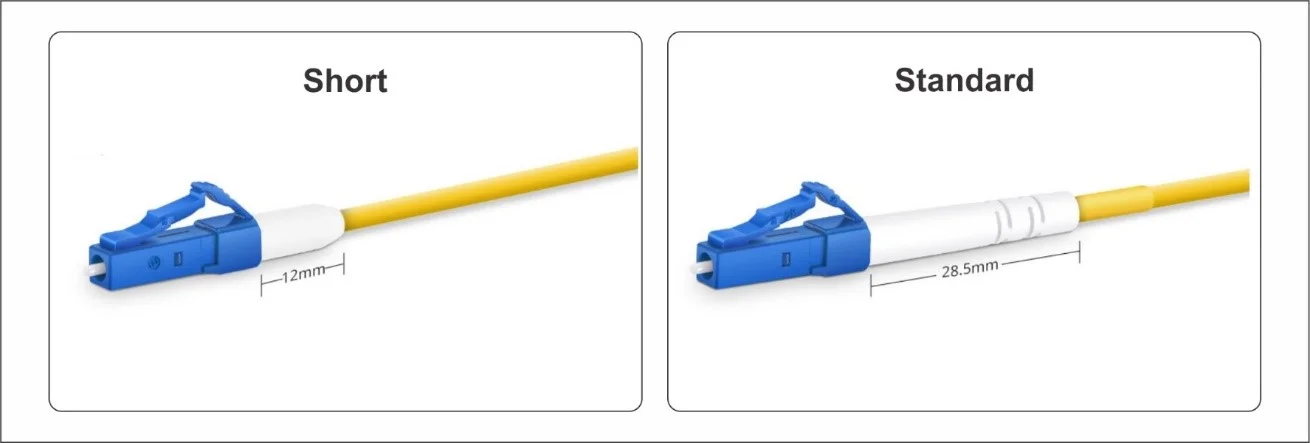

4. CONNECTOR BOOT TYPES

- Standard Boot: Longer, provides strong strain relief and protection; best for open spaces.

- Short Boot: Compact design for tight spaces like racks and high-density panels; easy to install and maintain.

Usage Environments for Fiber Connectors

1. FTTH / Telecom Networks

In Fiber to the Home (FTTH) and broader telecom deployments, maintaining low signal loss and high return loss is essential. SC/APC and LC/APC connectors, with their angled end-face polish, significantly reduce back reflection, making them ideal for high-speed and long-distance transmissions.

Explore Star’s FTTH Drop Solutions — pre-terminated and field-terminated kits designed for fast, reliable installations in residential and urban areas, compatible with top fusion splicers for consistent performance.

- Optical Line Terminals (OLTs) and Optical Network Units (ONUs)

- Last-mile fiber connections

- GPON/EPON systems

2. Data Centers

Data centers demand high-density, high-speed connectivity. LC/UPC connectors offer precise alignment and low insertion loss, while MPO connectors support multi-fiber connections, essential for 40G/100G parallel transmission.

Star’s Structured Cabling Solutions — featuring high-density patch panels, trunk cables, and MPO-to-LC breakout assemblies designed for scalable, high-performance data center networks.

- Core-to-edge connectivity

- Storage Area Networks (SAN)

- High-speed backbone links

3. Medical Systems

Medical equipment requires compact and high-precision connectors to ensure accurate signal transmission for diagnostics and imaging. MU connectors are particularly suited for miniaturized devices, while LC connectors offer reliability in limited space.

Why It Matters:

Signal clarity and zero disruption are critical in clinical environments where fiber optics enable real-time monitoring and imaging.

- Endoscopic and imaging equipment

- Diagnostic systems

- Surgical visualization tools

4. Military / Industrial Applications

Harsh environments such as military operations and industrial automation require ruggedized connectors that can withstand shock, dust, moisture, and extreme temperatures. FC connectors ensure stable performance in vibration-prone settings, while MIL-grade DIN connectors meet strict durability standards.

- Defense communication systems

- Aerospace and aviation networks

- Remote sensing and industrial control systems

Ruggedized Cable Systems — Built to military and industrial-grade standards, offering superior resistance and reliability in the most demanding environments.

Why Choose Star Technologies for Your Fiber Optic Needs?

At Star Infomatic, we do more than just supply fiber optic components—we empower complete fiber network deployments with cutting-edge technology and expert support. Our commitment to quality and innovation sets us apart in the industry.

Industry-Leading Equipment

Our portfolio features state-of-the-art fusion splicers, including the FFS 5000 Ultima, designed for precision splicing and reliable performance in the field. Alongside these, our Fibershot PRO Series OTDRs provide advanced testing capabilities to ensure your network’s integrity from start to finish.

Comprehensive Tools & Support

Beyond splicers and OTDRs, we offer a full range of fiber optic tools such as cleavers, splicing toolkits, and testing equipment tailored to meet diverse project requirements. Plus, our 24/7 toll-free support and on-site training services ensure your team is equipped and confident for every installation.

Trusted by Leaders

Star Technologies’ connectors, kits, and testing tools are trusted by India’s leading telecom providers and government-backed projects, reflecting our reputation for quality and reliability.

Conclusion

In fiber optic networking, every connection counts. With precision-engineered connectors and the right tools, networks can achieve superior uptime, faster speeds, and extended service life.

Choose Star Technologies for unmatched quality, innovation, and dependable performance. Whether you’re building smart cities, telecom grids, or enterprise infrastructures, we’re here to help you connect your world with the power of light.

Request Call Back

Request Call Back WhatsApp us

WhatsApp us